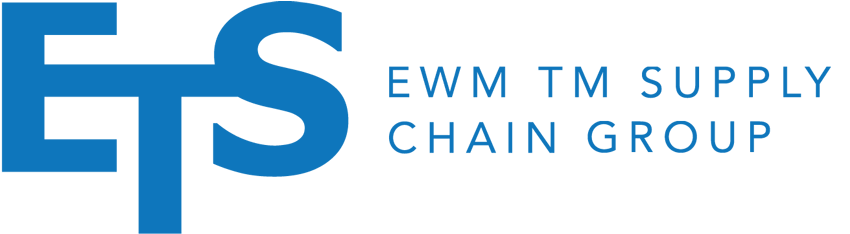

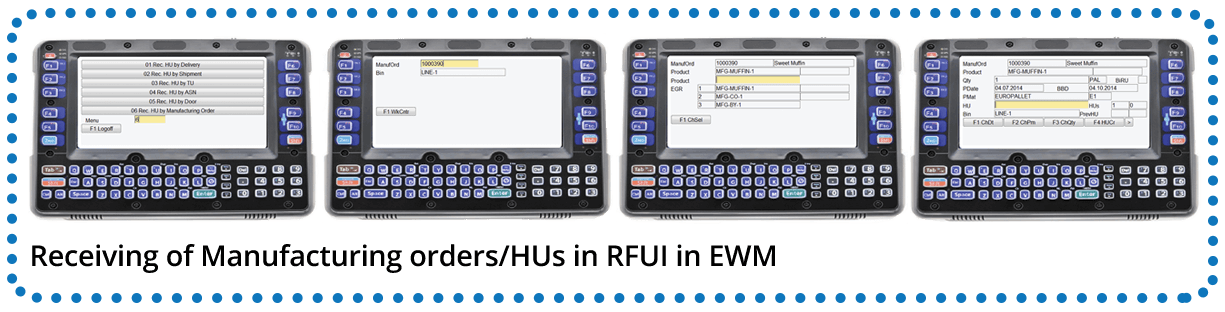

With release EWM 9.2 the integration of SAP EWM and SAP ERP PP/PI has been enhanced. An expected goods receipt (EGR) document is generated from the manufacturing order. Once the pallet has been identified in the inbound staging area, an HU and inbound delivery is automatically created from the EGR. The goods receipt can now be posted in ECC with either a direct Material Document, or through the creation of an Inbound Delivery in ECC. In the case where a Manufacturing Execution System (MES) is linked to the warehouse, MES may send a message to EWM prior to the arrival of an HU using a new API within EWM. The MES message is used in the warehouse to prepare the documents (e.g. inbound delivery item with planned HU) needed to receive and put away the HU in a minimal amount of time before the next HU arrives on the conveyor.

As process orders typically use batch-managed products, the HU-related GR shall offer the possibility to create new batches (a process order may produce several batches) or update existing batches (process order contains the batch number, but batch has no attributes yet).

In case an HU was received twice (e.g., label fell off), a receipt correction can be executed in EWM to reverse the HU receipt. It is also possible to reverse a partial quantity of an HU which was over-received. Both use cases are now possible. The receipt from production also works for HUs of semi-finished products where receiving should take place in the production supply area or another production step without additional steps.