EWM Case Picking Functionality

Technologies to improve manual case picking productivity, accuracy and throughput include:

- Voice-directed picking

- RF-directed picking

- Pick/Put-to-Light (PTL) picking

For higher volume case picking applications, walk-pick-to-conveyor modules with pallet and case flow racks incorporating Voice, RF or PTL technologies enable very high productivity rates to be achieved.

Key business benefits include:

- Increased productivity

- Reduced labor costs

- Faster order fulfilment

- Improved order accuracy

- Better stock rotation

- Enhanced customer service

- Real-time operational visibility and decision support metric

Pick, Pack & Pass

What is Pick, Pack & Pass?

This function to coordinates picking, packing, and passing of products in different activity areas in the warehouse. For example, transporting products from one activity area to another using a conveyor belt. From an organizational point of view, an activity area can correspond to an aisle, for which a warehouse worker is responsible. Once a warehouse worker has picked a warehouse order, the warehouse worker passes on the goods.

Using this function, the system creates a higher-level warehouse order that contains the pick-HUs for all warehouse tasks that are to be created, which are picked one after each other. The warehouse worker also receives the warehouse order created for the workers activity area, together with its warehouse tasks.

The Pick, Pack and Pass function is most efficiently used in an RF environment. The process flow is the same as for “standard” RF picking. Make the Customizing settings mentioned in the prerequisites in Extended Warehouse Management.

Concept

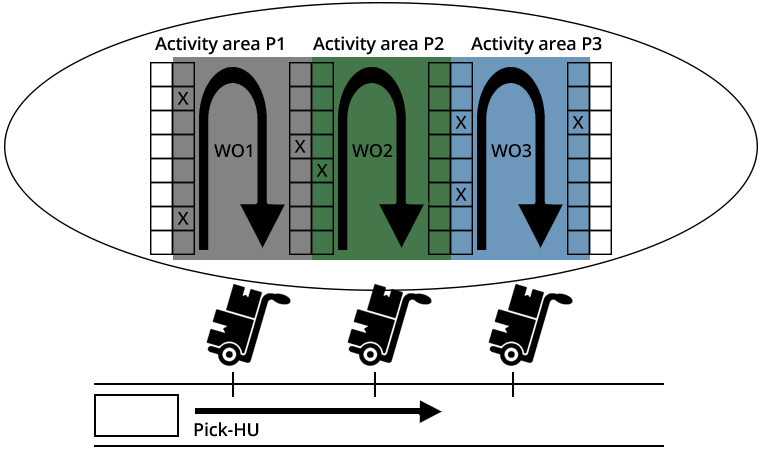

The basic premise behind the Pick, Pack and Pass concept is to have the warehouse broken down into multiple Activity Areas (zones) within which picking is managed, and picking across those zones in a prescribed sequence, handing off the picked goods in one zone to a picker in another zone to add additional goods until either the Pick HU is full, or the order is completely picked.

As the AA in EWM causes a split during Warehouse Order Creation, Pick, Pack and Pass provides a means to join picks across AA together. A higher level AA is defined to establish that joined relationship, and a higher level WO is created as well. The following image from SAP illustrates this concept. Each aisle (shown by the different colors) is its own individual AA. All 3 AA area joined together into a higher level AA. A WO for picking is created in each aisle/AA, and an additional WO is created to tie it all together. The work is then executed by three different resources (pickers).

Higher-Level Warehouse Order – Higher-Level Activity Area

Where do I use Pick, Pack & Pass?

The Pick, Pack & Pass concept can be applied to several different types of warehouse layouts and process flows:

- Warehouses with a Conveyor system where picks are done into a Tote

- Warehouses with separate Layer-Pick and Case-Pick areas

- Warehouses with separate Pallet and Case Pick areas